HKM CB20 Crusher Bucket

HKM CRUSHER BUCKET – CB20

HKM CB20 Crusher Bucket is a mid-size excavator attachment engineered for 16–25 ton carriers.

With its reinforced steel frame and high-efficiency hydraulic drive, it enables direct crushing of concrete, asphalt, bricks, and other demolition materials on site. The CB20 reduces haulage and tipping expenses while significantly accelerating project timelines by allowing mobile crushing at the jobsite.

Equipped with a bucket volume of 0.75 m³ and an operating weight of 2,290 kg, the CB20 offers both high throughput and mechanical durability. The hydraulic setting mechanism enables quick adjustment of output sizes between 15–130 mm, depending on the material. At an 80 mm setting, it delivers a production rate of up to 40.1 tons per hour.

Its quick-swap jaw system minimizes maintenance downtime. Combined with uninterrupted feed and integrated loading ramp design, it ensures continuous and efficient operation, particularly suited for infrastructure projects, road construction, and urban demolition work.

KEY FEATURES

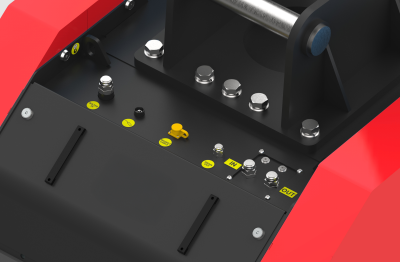

- Reinforced Steel Housing: Heavy-duty wear-resistant frame with replaceable liners for long-term durability

- High-Efficiency Hydraulic Drive: Axial piston motor and belt-protected valve extend motor life and ensure consistent performance

- Quick Jaw Replacement: Upper and lower jaws are replaceable in minutes, reducing downtime

- Uninterrupted Feed Cycle: Enables efficient loading and crushing without material blockage

- Adjustable Output Size: Hydraulic setting allows for 15–130 mm grain size

- High Throughput: Up to 40.1 tons/hour at 80 mm output grain size

APPLICATION AREAS

- On-site recycling of concrete, asphalt, and brick

- Road fill production and trench support in infrastructure works

- Primary reduction of quarried or riverbed stone

- Curb and pavement rehabilitation in urban environments

- Underwater concrete removal in drainage and water infrastructure

OPTIONAL EQUIPMENT

- Dust Suppression System: Integrated water spray system for a cleaner and safer crushing environment

- Centralized Lubrication System: One-button grease delivery for all bearing points

- Electromagnetic Iron Separator: 24V-powered rebar and scrap steel separation directly from the excavator

TECHNICAL SPECIFICATIONS

| Carrier Weight (ton) | 16–25 |

| Operating Weight (kg) | 2,290 |

| Bucket Volume (m³) | 0.75 |

| Jaw Height (mm) | 510 |

| Jaw Width (mm) | 800 |

| Output Size (mm) | 15–130 |

| Oil Flow (LPM) | 150–220 |

| Production Capacity (t/h @80mm) | 40.1 |

CUSTOMER REVIEWS

No reviews yet. Be the first to review this product!